jaw rock crusher design

jaw rock crusher design

Blake Jaw Crusher - Mineral Processing & Metallurgy

15/01/ · The original Blake crusher was designed with a vertical stationary jaw. Probably the first departure from this arrangement was an 84 X 66″ crusher, built in 1914. This machine

Learn More

Design and Construction of Rock Crushing Machine from

The jaw crusher is a rocks or lumps reduction machine The design and construction of a prototype rock crushing machine was performed

Learn More

Jaw Crushers | McLanahan

The Jaw Crusher was first introduced by Eli Whitney Blake in 1858 as a double-toggle Jaw Crusher. Introduced in 1906, McLanahan's Universal Jaw Crusher was one of the first modern era overhead eccentric Jaw Crushers. On the overhead eccentric style Jaw Crusher, the moving swing jaw is suspended on the eccentric shaft with heavy-duty double

Learn More

What is a Jaw Crusher? - MEKA Crushing Equipment

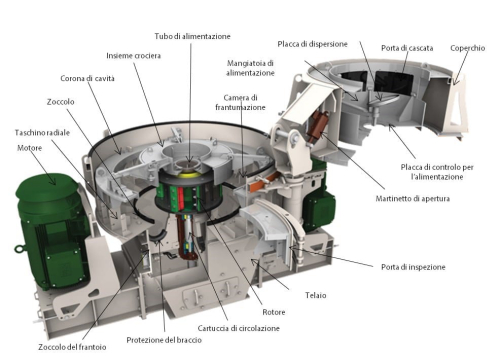

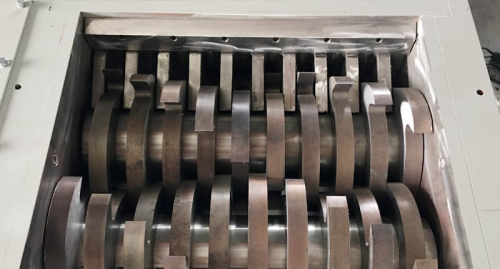

All jaw crushers feature two jaws: one of which is fixed while the other moves. The working principle of jaw crushers is based on the reciprocating movement of the movable jaw that compresses and crushes the rock or ore between itself and the fixed jaw, as the material enters the zone between the jaws.

Learn More

SMAN jaw crusher - Shakti Mining

a jaw crushers is a crushing machine designed considering a primary stage crushability for materials such as rock, mineral, rom and building rubble. jaw crushers design focuses on compression type crushing with feed of material being received from the top of the crushing chamber that consists one side fix and other movable type cast manganese jaw

Learn More

Jaw Crusher - an overview | ScienceDirect Topics

The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation. The capacity is primarily a function of: 1. crusher design characteristics such as width and depth of the crushing chamber, 2. open and closed side settings, 3.

Learn More

AMIT 135: Lesson 5 Crushing - Mining Mill Operator Training

Jaw Crusher Capacity · crusher design characteristics such as width and depth of crushing chamber. · open and closed side settings. · options on feeding method,

Learn More

Two Design Awards for Kleemann EVO2 Crushing Plants

The German Design Award and Good Design Award for new mobile jaw and cone crushers of the new EVO2 generation. With these awards, Kleemann has once again

Learn More

PDF) Design and Construction of Rock Crushing Machine

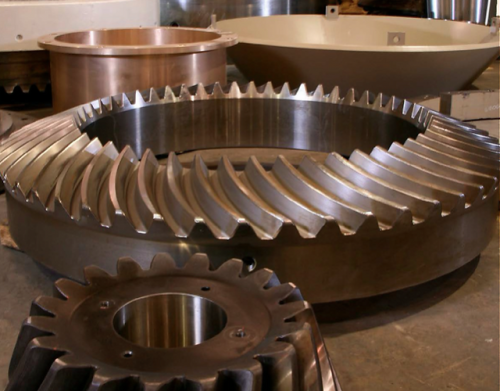

jaw crusher machine is made of hardened steel (high carbon steel). It puts the moveable jaw stock in motion (through the motor, pulley. and belt

Learn More

Development-Design-for-Jaw-Crusher-Used-in-Cement

crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust.Crushers may be used to reduce the size, or change the form, of

Learn More

Jaw Crusher Explained - saVRee

A crusher is a machine designed to reduce the size of large rocks to smaller rocks , gravel , sand, or rock dust; this is essential for efficient transport of the product via conveyors etc. Crushing

Learn More

Eagle Jaw Crushers

Eagle Jaw Crushers eliminate premature failures to provide years of component life, durability, and reliability for your crushing applications. Processes abrasive hard rock, using the time tested overhead eccentric design. The short bearing span between the side frames reduces stress and shaft deflection.

Learn More

Jaw Crusher - JXSC Machine

Jaw Crusher. 【Capacity】 1-130tph. 【Feeding Size】 <1200mm. 【Output Size】 10-300mm. 【Crushing Materials】Granite, dolomite, river pebbles, quartz, calcite, and other materials. 【Application】 Jaw crushers are mainly used at the primary stage to reduce hard and brittle materials size for the next crushing stages, widely applied

Learn More

How Does a Jaw Crusher Work | Jaw Crusher | Kemper Equipment

More compact than double toggle designs, the single toggle movement jaw crusher was at one time unable to accept such large feed sizes, though it can typically run faster. the bottom of the “V”-aligned jaw plates is the output gap that dictates the size of the crushed product from the jaw crusher. The rock remains in the jaws until it

Learn More

How to Build a Rock Crusher | Home Guides | SF Gate

21/07/ · 6. Quickly insert the 3-foot iron rod into the cement. Move it until it stands at the center of the pipe. You may have to prop it in place by fixing a C-clamp to it and laying the clamp on the top

Learn More

Computer Aided Design of Jaw crusher” - ethesis

The pitman moves on an eccentric shaft and swing lever swings on centre pin. The rock is thrown between two jaws and crushed by mechanical pressure. A belt

Learn More

Jaw Crusher Design;jaw Crusher Stroke

Jaw Crusher is a kind of Stone crusher, and jaw crusher is also called Rock crusher. This series of Jaw crushers have many advantages which mainly used in breaking a jaw crusher design, jaw crusher operation jaw crusher should be carefully designed to provide superior quality and performance with low power consumption and easy maintenance.

Learn More

en/plans for a jaw crusher.md at main · /en - GitHub

Simplicity of design and rugged construction has made jaw crushers ideal This 1″ x 2″ homemade rock crusher is mini in size but large in crushing

Learn More

Rock Crusher New Design Mining Machine Jaw Crusher

Rock Crusher New Design Mining Machine Jaw Crusher Stone Crushing Line Factory, Find Details about Crusher, Pev Jaw Type Crusher from Rock Crusher New

Learn More

Material Selection for Crusher Jaw in a Jaw Crusher Equipment

The purpose of this paper is to select a suitable candidate material for the design of crusher jaw that can sustain fracture by any of the

Learn More

Double Toggle Jaw Crusher Design

The DT (Double Toggle) Model Jaw Crusher is unique in that it has its hinge The advantage of this design is that when the movable jaw Jaw crushers,Jaw breaker, Primary,Mobile,Stone jaw crusher Double Toggle jaw crushers may feature hydraulic toggle adjusting mechanisms. Our design and production are of high position both at home and abroad.

Learn More

Jaw crusher machine design pdf - Australian Manuals Step-by

08/07/2022 · aj series jaw crushers CITICHeavy Industries Co. Ltd. Dec 8, The design of the AJ series uses a bolted and pinned frame assembly, with The AJ series Single toggle jaw crusher incorporates the use of the hybrid however please consult CITICHIC for your specific requirements. jaw crushin machine – tisl.

Learn More

22 Crusher ideas - Pinterest

DIY Impact Mill/Rock Crusher - Crush Anything (Gold Ore, Circuit Boards, etc) ACME Jaw Crusher Wholesale Supplier | Used ACME 1530 Jaw Crusher For Sale.

Learn More

Jaw Rock Crusher - 911Metallurgist

The 911MPETMBT75 is our largest Laboratory Jaw Rock Crusher and is based on our world-renowned High Reduction Ratio Jaw Crusher, the 911MPETMBT75 has been engineered to

Learn More

DESIGN AND OPERATIONS CHALLENGES OF A SINGLE

DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER: A REVIEW Performance optimization of jaw-type rock crushing machine

Learn More

Computer Aided Design of Jaw crusher

opening of 22" by 30", a 46 x 46 jaw crusher has a opening of 46" square. Generally primary jaw crushers have the square opening design, and secondary jaw crushers have rectangular

Learn More