cone crusher liner

cone crusher liner

Bowl Liner & Mantle | Wear Resistant Crusher Parts | GTEK

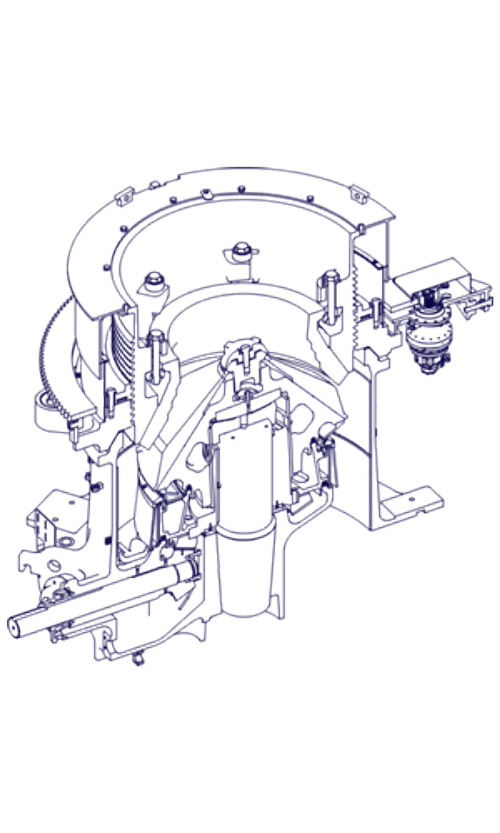

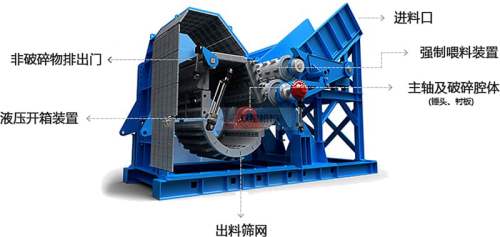

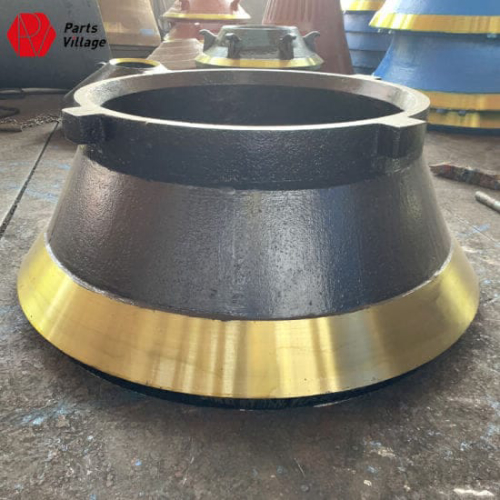

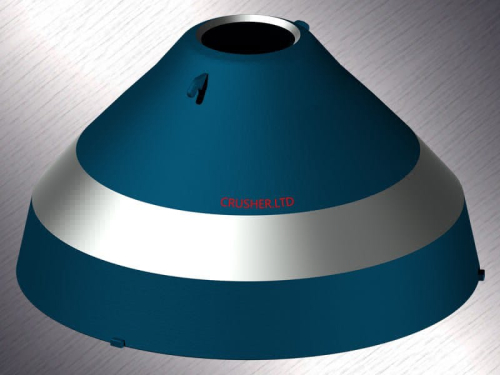

Cone crushers are widely used in the mining and aggregates industries to reduce the size of blasted rock by compressing the material between two manganese liners: mantle and bowl liner. The mantle covers the cone head to protect it from wear, we can see it as a sacrificial wear liner that sits on the cone head.

Learn More

Cone Crusher Wear Parts - Unicast Inc

Durable cone crusher wear parts - bowls and mantles, liners, torch rings, and distributor caps engineered to exceed OEM wear life performance.

Learn More

Cone Crushers | McLanahan

A Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of steel.

Learn More

How To Select Cone Crusher Liners and When To Change Them

The Cone Crusher liner should have a well-graded feed flowing into the crushing chamber. This generally consists of: 90 to 100 percent passing the closed-side feed opening 40 to 60 percent going through the midpoint 0 to 10 percent leaving the closed-side setting Match the entire feed gradation and not only the feed shape.

Learn More

Selecting crushing chambers for cone crusher

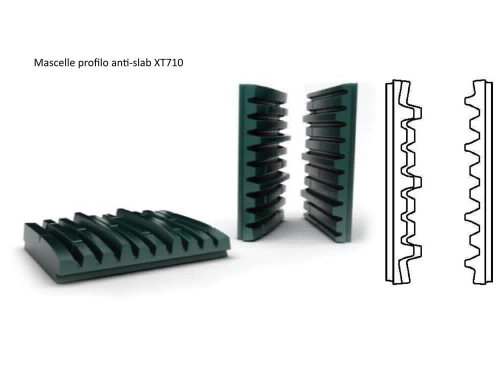

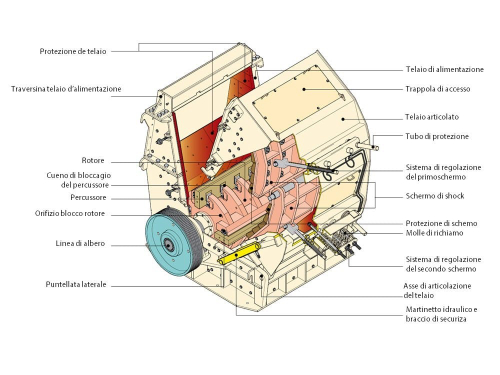

Illustrative figure of HP cone crusher liners. To ensure the suitability of the liner profile for its application, it is important that

Learn More

Replacing the liner of a HP cone crusher - Outotec

09/06/ · The HP cone crusher is a very important piece of equipment in a crushing plant. It can operate as a secondary, tertiary or quaternary crusher, depending on the crushing process.

Learn More

Cone Crusher Liners | Crushing Wear Parts

CSP is a leading supplier of cast, forged, and fabricated wear solutions to OEM and aftermarket crusher operators. We have over 30 years' experience

Learn More

Efficient Utilization of Rock Crushing Equipment Wear Liners

In the case of cone crushers, as the liners wear down, the feed opening at the top of the crusher will constrict, and you'll lose throughput

Learn More

Common Faults and Solutions of Cone Crusher

6. Strong vibration of cone crusher. The reason. The device base fixture may be loose. There are hard-to-crush materials in the crushing cavity of the cone crusher. Too much material in the crushing cavity causes blockage. The liner is broken or worn. Poor lubrication causes the spindle to be wrapped tightly by the bushing. Solution

Learn More

Cone Crusher Liners - Valley Rubber, LLC

Cone Crusher Liners offer considerable reduction in noise and are generally lighter in weight and offer significantly longer life than their steel

Learn More

buy cone crusher liner

buy cone crusher liner · استشارة المعدات · jaw Ore Mining Replacement Suit for HP300 Cone · Crushers · Full Service Mobile Limestone Crusher For Sale · USA1 · Which

Learn More

Cone Crusher Solutions - Bradken

Overview · Customised liner profiles to suit all operating conditions · Manganese grades to cover all applications · Direct Replacement Part(DRP) crusher liners

Learn More

Cone Crusher Liners | Manufacturing and service of

Cone Crusher Liners — find the correct solution for your application. Using our knowledge as an Original Equipment Manufacturer (OEM), we ensure that the supplied product is correct for

Learn More

Cone Crusher Liners For Popular Brands With Various

It is the outer sacrificial wear liner that sits inside the upper frame. Common Aliases: Cone crusher liners, Cone crusher wear parts, Manganese cone liners,

Learn More

Crusher Liners - Luoyang Hengin Heavy Technology Co., Ltd

HENGIN'S OEM Crusher Spare Parts products include hydraulic cone crusher, jaw crusher, gyratory crusher main frame, adjusting ring, copper sleeve, bearing,

Learn More

Prediction Model for Liner Wear Considering the Motion

Introduction. Cone crushers are important comminution devices in mineral processing and cement production. While the cone crusher is working,

Learn More

Change Cone Crusher Liners - MGS Casting

1. On the initial set of new linings, put a mark on the change cap chauffeur ring where the pinion tooth reaches a chauffeur ring tooth when the target crusher setting has actually been achieved. 2. Keep an exact record of the variety of teeth made use

Learn More

Cone Crusher Liners Selection - Wear Parts For Industry - Qiming

2.Crusher Liner’s Material. Cone crusher wear parts, concave and mantle, are casting by manganese steel. Mangalloy, also called manganese steel or Hadfield steel, is a steel alloy

Learn More

Cone Crusher Liners - EB Castworld % Cone Crusher Liners

Cone Crusher Liners are the main components for crushing materials in the cone crusher. Cone Crusher Liners have U-shaped screws on the adjusting ring. Zinc alloy is injected between the

Learn More

Cone Crusher Wear Parts - Columbia Steel Casting Co., Inc

For better production and longer wear life, choose Columbia cone crusher liners. · Standard, heavy-duty, and custom wear parts for all popular cone crushers.

Learn More

Cone Crusher Liners - SHANVIM

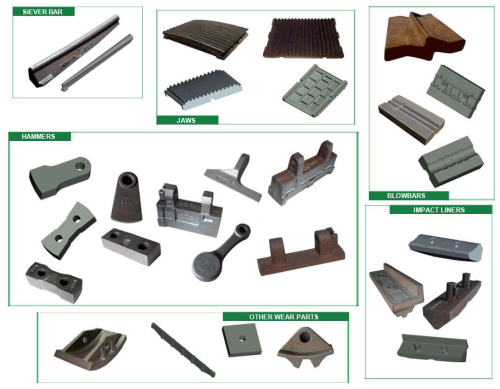

Cone Crusher Liners - Manufacturers, Suppliers, Factory from China. We have state-of-the-art tools. Our products are exported towards the USA, the UK and so on, enjoying a fantastic reputation amongst customers for Cone Crusher Liners, Qms Blow Bar, Hammer for scrap metal recycling industry, Crusher Toggle Plate, Ceramic Crusher.

Learn More

Cone crusher parts - Wear Parts For Industry | Qiming Casting

Mn18Cr2. Mn18Cr2 is the most popular material for casting cone crusher liners. This Mn18Cr2 cone crusher liners widely in crushing difficult and non-abrasive blasted rock, medium and non-abrasive,non-abrasive gravel, and non-abrasive round rock. Mn22Cr2. Mn22Cr2 cone crusher liners are widely used in crushing hard and abrasive stones.

Learn More

Cone Crusher Liners For Popular Brands With Various Material

Cone crusher concave, which sits in the upper frame of the crusher to protect it from wear. It is the outer sacrificial wear liner that sits inside the upper frame. Common Aliases: Cone crusher

Learn More

cone crusher liners At The Best Prices

Crusher Liner Cone Crusher Longer Service Life Stone Crusher Spare Parts Mantle Bowl Liner For Spring Cone Crusher Machine. $2.50-$2.80/ Kilogram. 100 Kilograms (Min. Order) 5 YRS CN. Supplier.

Learn More

Analysis of the Wear Failure of Cone Crusher Liner at Copper Mine

17/01/ · From the first picture “Wear Morphology After Cone Crusher Liners Failure x100”, The cone-crushing motorized lining plate performs an eccentric rotation motion. When it is deflected to the fixed lining plate, it will give a huge impact load to the broken ore, causing the lining plate to be squeezed and plastically deformed.

Learn More

Cone Crusher Liners | Manufacturing and service of Gyratory Crushers

Cone Crusher Liners — find the correct solution for your application. Using our knowledge as an Original Equipment Manufacturer (OEM), we ensure that the supplied product is correct for your equipment and application. We offer Cone Crusher Liners tailored to your needs and manufactured to help you find increased productivity.

Learn More