v-belt drive design calculation pdf

v-belt drive design calculation pdf

V-Belt Design Manual - All World Machinery

Procedure 1: Calculation of Design Horsepower Calculate the design horsepower from the following equation. Example: Customer needs a V-belt drive for an agitator that is in

Learn More

DHANALAKSHMI COLLEGE OF ENGINEERING - MECH DCE

suggest a suitable multiple V- belt drive for this application. Also calculate the actual belt tensions and stess induced. DESIGN OF V- BELT DRIVES USING BASIC

Learn More

Complete Guide To Design V-Belt Drive Systems With Calculators

Steps To Design V-Belt Mechanism, V-belts are common construction elements on internal combustion engines. Step 1: Define the rated power for driving electric motor or shaft; In v-belt systems, there is always a prime mover that gives the motion to the system. This moving energy would come from an electric motor or a moving shaft.

Learn More

timing belt, V-Belt and Flat Belt Design and Engineering Formulas

V-belts need larger pulleys for their thicker cross-section than flat belts. For high-power requirements, two or more V-belts can be joined side-by-side in an arrangement called a multi-V, running on matching multi-groove sheaves. This is known as a multiple-V-belt drive (or sometimes a "classical V-belt drive").

Learn More

Drive & Tension Calculator, CAP - OPTIBELT

Optibelt WebCAP is an easy-to-use online drive design and tension calculation tool. It can be used without the need to register and there is no software to install. Click on the link above to go to the WebCAP site. WebCAP can be used for simple 2-pulley v-belt drives to design for optimal efficiency or to calculate proper tension values.

Learn More

V-belt drives - Tribology

V-belt drive design, calculator for shaft load, software, calculator V-belt drive Transmitting power P kW Rotational speed driver pulley n 1 rpm Diameter driver pulley D 1 mm Diameter driven pulley D 2 mm Center to center distance mm β deg Coefficient of friction

Learn More

PDF Belt Conveyors CalculationsPDF

1. rolling resistances of the idlers 2. flexing resistance of the belt 3. flexing resistances of the bulk material 4. acceleration resistance and frictional resistance between material handled and belt 5. chute frictional resistance 6. scraper resistance 7. deflection resistance due to belt bending 8. gradient resistance of conveyed material , W,

Learn More

Belts and chains

v) They are simple to design. (vi) They have low initial cost. Belt drives are mainly used in electric motors, automobiles, machine tools and conveyors.

Learn More

151042913-Design-Calculation-of-Pulley-Belt-Drive.pdf

PULLEY & BELT CALCULATION – M.S.GURU 1. Selection of belt section : Select the type of a belt depending on the power to be transmitted. (see V-Belt Table in pg no:7.58 ) Example : For power 100 Kw, D section is selected. (see V-Belt Table in pg no:7.58 ) Motor power = 100 kW Motor speed(N 1) = 1440 rpm Pump speed(N 2) = 340 rpm 2. 2.

Learn More

V belt design guide - Embedded Eye

2022/7/31 · v-belt drive design calculation pdf v-belt sizes chart in mm belt tension formula pdf v-belt horsepower capacity v-belt design calculation v-belt catalogue pdf how to calculate hp per beltv-belt specification chart Design Manual. V-Belt. Classical V-Belts for DIN

Learn More

Useful Formulas and Calculations

V = Belt speed, ft/min. Design Horsepower = hp x SF. Where: hp = Horsepower. SF = Service Factor. Torque (lb-in) = 63025 (hp) rpm. Where: hp = Horsepower.

Learn More

Calculation of V-Belt Tensions And Shaft Loads - MPTA

MPTA-B7i-2007R Calculation of V-Belt Tensions And Shaft Loads Mechanical Power Transmission Association 5672 Strand Court, Suite 2, Naples, FL 34110 www.mpta.org Page 7

Learn More

V-BELTS.pptx - DESIGN PROCEDURE OF V-BELT (Using Basic Equation) Step 1:Determination of Velocity of Belt Velocity of Belt V= Step 2: Calculation

A 50 kW motor running at 1000 rpm is required to drive pump pulley at 400 rpm space restrictions limit the size of motor pulley 0.3 m and the center distance is 2.5m. The pump is located in a shed and is expected to run for 16 hr/day . Select a suitable V belt drive and design.

Learn More

Balflex Power Transmission V-Belts

Balflex® Extreme is the narrow trapezoidal V-belt range of Balflex®, according Compact drive design: Better dynamic characteristics allow smaller sheave.

Learn More

PDF DESIGN OF FLAT AND V BELT DRIVES - icet.ac.inPDF

Design and construction of flat belt 5. Design and construction of V belt drive is sunple and inexpensive and drive is complex and costlier. easy to maintain. 6. They have large dimensions and 6. V belt have short centre distance consume much higher space for which results in compact construction operation.

Learn More

PDF Optibelt Timing Belt Technical Manual - bearingtraders.comPDF

for the belts usage. Furthermore, the calculation met-thods for the drive design with OMEGA, OMEGA HP, OMEGA Fan Power and OMEGA HL timing belts is also presented. The belt characteristics described may change due to various influences. Thus, the drives must be designed based on their future use (or in a way that comes close to their future use).

Learn More

PDF Belt Conveyors for Bulk Materials Practical Calculations - PDHonline.comPDF

3. belt conveyors - basic calculations: 4. cema belt tension theory: 5. troughed belt conveyor capacities: 6. belt carrying idlers or belt troughed rollers: 7. cema troughed idlers: 8. standard belt conveyor pulleys: 9. belt conveyors accessories: 10. basic design criteria: 11. loading of belt and impact rollers: 12. belt conveyor covers: 13.

Learn More

TECHNICAL AND DRIVE DESIGN FOR V-BELTS

4, For multiple drive, use as many V-belts required for better service life and low maintenance STEP 3 - Calculate Design Power (Pd).

Learn More

Belt drive online design calculation | Hutchinson Belt Drive Systems

Belt drive design calculation. Discover Hutchinson calculation belt drive design softwares : Poly V design and Wizard Conveyxonic. Hutchinson : Belt drive power transmission Hutchinson develops and manufactures complete power transmission system incorporating ribbed belts for HVAC, Conveying, industrial motors, agriculture and energy supply markets.

Learn More

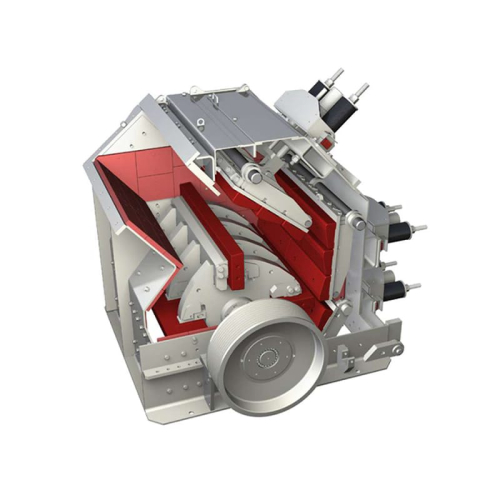

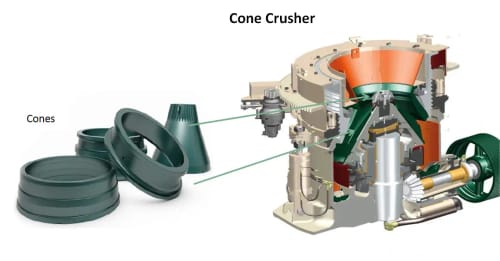

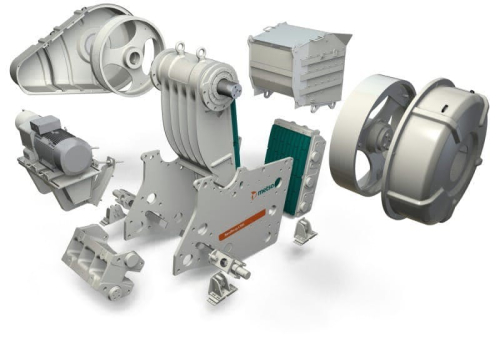

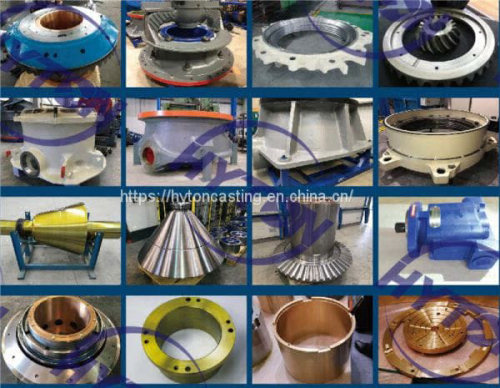

HP500 COUNTERWEIGHT v-belt drive design calculation pdf

HP500 COUNTERWEIGHT v-belt design pdf spare parts. Metso. Spare parts for Cone. Head Assy ,Bowl ,Drive Gear , Counterweight assy,Shaft ,Pitman Genuine Mercury & Mercruiser parts. 90-840283R01 500 EFI. We have Mercury Hi-Performance 500 EFI service manuals in stock. Order genuine factory OEM part number 90-840283R01 at a

Learn More

V-belt Drive | Online Calculator

Below, you can calculate the two-pulley V-belt drive. To perform the calculations, it is necessary to set the rotational speed of the drive pulley n, power P, and gear ratio i. It is also necessary

Learn More

PDF Drive calculation - Stemin BreitbachPDF

Minimum pulley diameter depends on belt construction but alsoon the load and the configuration of the drive. The values repor-ted in the catalogue have been calculated and proven for driveswith maximum allowable load and standard configurations. For drives where smaller pulleys are needed, please apply toELATECH®technical department. ,

Learn More

V belt design guide - Embedded Eye - Ning

V BELT DESIGN GUIDE >> DOWNLOAD LINK V BELT DESIGN GUIDE >> READ ONLINE v-belt drive design calculation pdf v-belt sizes chart in mm belt tension formula pdf v-belt horsepower capacity v-belt design calculation v-belt catalogue pdf how to calculate hp per beltv-belt specification chart. Design Manual. V-Belt. Classical V-Belts for DIN. Maxstar Wedge V-Belts for RMA / Cross section selection

Learn More

V - Belt Drive for Mechanical Engineering | Engineers Gallery

8/22 · Fig. 1 V Belt Drive. V belts (also style V-belts, vee belts, or, less commonly, wedge rope) solved the slippage and alignment problem. It is now the basic belt for power transmission. They provide the best combination of traction, speed of movement, load of the bearings, and long service life. They are generally endless, and their general cross

Learn More

Drive Calculation - Stemin Breitbach

When installing belts on pulleys, before tensioning the drive, check that the belt teeth and pulley grooves correctly match. Breaking load. Belt breaking load

Learn More

ME-6601 DESIGN OF TRANSMISSION SYSTEMS

Under what circumstances chain drives are preferred over V belt drives? Calculation of design power in KW. Step 2: Calculation of design load:.

Learn More